Xinxiang Tongxin Machinery Co. LTD. was

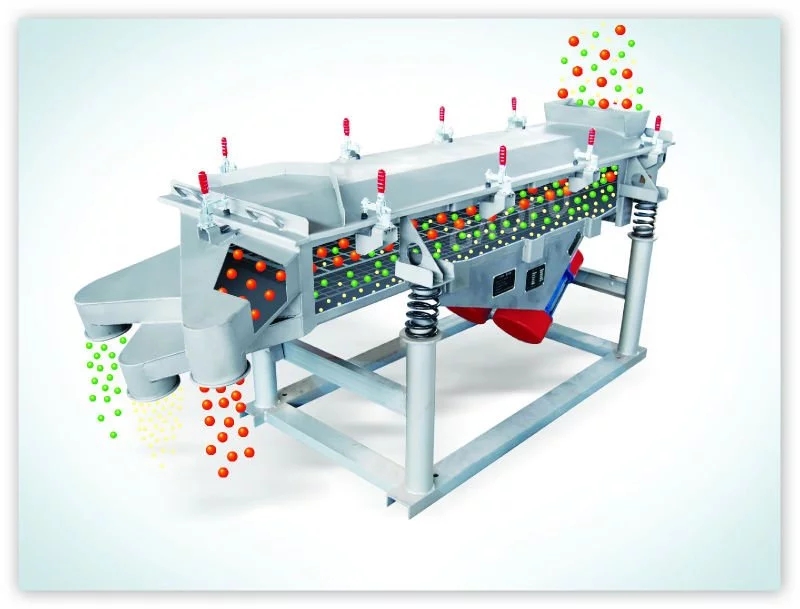

established in 1996, mainly design and manufacture vibrating screen

equipment, conveying equipment, lifting equipment, mixing

equipment, dust removal equipment and other kinds of powder

equipment.

After more than 20 years development with the support

of governments at all levels, we have 2 senior engineers and

several intermediate or junior engineers with independent design

and development capabilities. Xinxiang Tongxin Machinery has plant

covers an area of more than 2000 square meters and office building

covers an area of 800 square meters with 50 years of property

rights to laid a firm foundation for a long-term stable service.

Xinxiang Tongxin Machinery has a variety of CNC

machining equipment, such as machining center, CNC lathe, CNC

gantry drilling machine, CNC welding machine, CNC laser cutting

machine, CNC bending machine, CNC plate shearing machine, large

wave folding machine, metal netting machine, etc., we have now

reached automatic production of blanking, welding, machining and

other processes by cooperating with a large number of tools and

molds to form an automated production line, and is committed to

gradually realizing data interconnection and unmanned intelligent

production. The use of automation equipment has greatly improved

the production efficiency, and reduced the cost of a single

machine, so that Xinxiang Tongxin Machinery in the premise of

quality assurance to the general customers.

The designers of Xinxiang Tongxin Machinery are

committed to meet the differentiated requirements of different

users, we provide customized design services, improve product

adaptability, optimize the cost performance from the deep

understanding of the product working principle and user process. At

the same time, Xinxiang Tongxin Machinery is equipped with a large

number of testing and experimental equipment for the product

delivery test to ensure the product consistency and stability and

provide a high-precision products to users.

At present, Xinxiang Tongxin Machinery has been

exported to 46 countries on 5 continents, including North America,

Europe, Southeast Asia, South America, West Asia, Middle East and

Africa and we have over 13,000 active users in China. The main

users include international famous enterprises and advanced

scientific research institutions, the most representative are Air

China, CICC, China Metallurgical Group Corporation, CNPC, Sinopec,

Charoen, Pokphand, Chinese Academy of Sciences, China National

Medical Administration and so on.

The tenet of Xinxiang Tongxin Machinery is: "with

superb technology to deeply understand the needs of users, continue

to improve the quality, provide a full line of customization. With

high quality, first-class service to fulfill the commitment to

customers ". All the staff of our company are committed to

providing high quality service for customers.

In 2016, Xinxiang Tongxin Machinery was successfully

listed on the new fourth board.