All Specifications Test Sieve Machine Screening Accuracy Medicine

Industry

Description

The device is also called automatic sieving machine.It is

applicable to precision screening and grading of ultra-fine

powders.

With a high passing rate, it can screen and classify the material

whose size reaching to 500 mesh(the most detailed available to 5

microns), and which is light weight, easy to harden.

It is widely used in chemical industry, metallurgy, medicine, food,

building materials and other industries.

Specification

Features

1. High efficiency and design with exquisite and durable, any

powder or liquid can be sifted.

2. Small volume, no space and easy to move.

3. The screen machine can place an eight-layer test screen

(including the bottom of the screen), which can accurately divide a

kind of particle material into 2 ~ 7 particle sections at the same

time.

4. Automatic shutdown can be timed to ensure the repeatability of

the experiment, complete functions and simpler operation, low noise

and light weight.

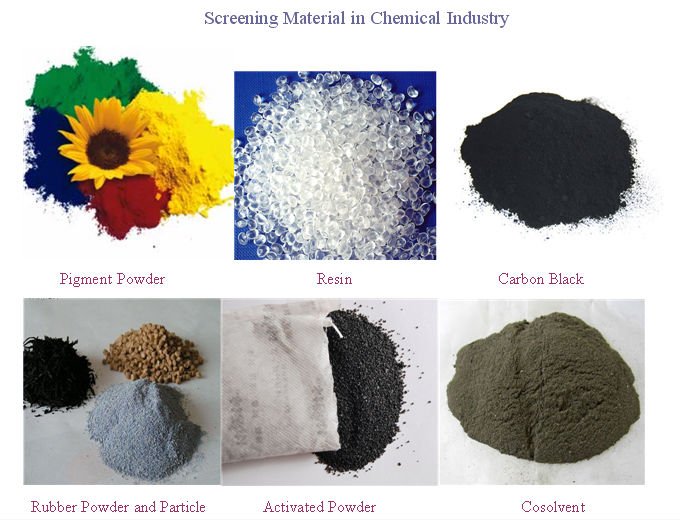

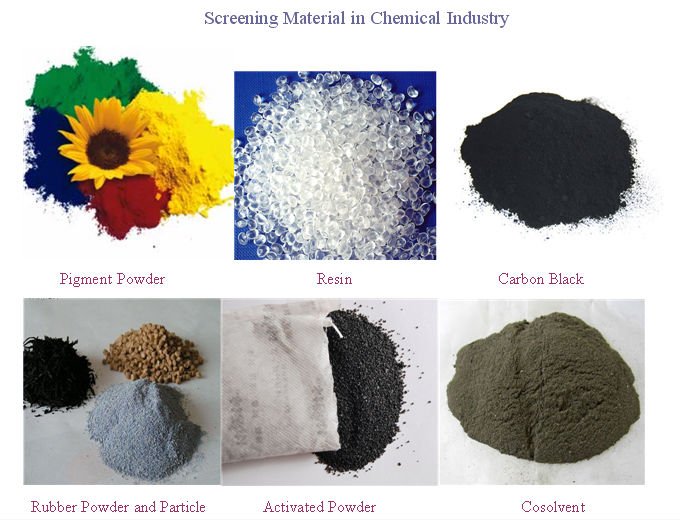

Apply in Industry

Widely used in food, medicine, chemicals, abrasives, pigments,

mining, metallurgy, geology, ceramics, and national defense

industry, It is used in the scientific research units,

laboratories, testing labs, production and control to test, screen,

grade, analyse the particles, analyse debris content of solid,

powder, slurry feed materials and so on.

Working Principle

ZS Lab Sieve adopts new type power generator that generates

multivariate high-frequency vibration to sieve and filter samples

efficiently. Meanwhile, its standard screen makes sure sample

analysis of high precision. At the same time, it uses upright motor

as the source of vibration.

The vertical motor, which is installed with eccentric hammers on

the top and bottom, is regarded as vibratory source.

The eccentric hammers change the track of rotation into horizontal,

vertical and inclined movement, and then pass the movement to the

sieving surface. Adjusting the phase angle between the top and

bottom eccentric weight can change trajectories of the materials on

the sieve.

Technical Parameters

| Number | Name | Units | Numerical Value |

| 1 | Screen Diameter | mm | 200,100,75(can be customized) |

| 2 | Screen Layer | layer | 1-7(no ultrasonic), 1-3(ultrasonic) |

| 3 | 200 Test Screen | set | Full range is available |

| 4 | Shake Distance | mm | 25 |

| 5 | Motor Power | W/V | 90:220 |

| 6 | Motor Speed | rpm | 0-290(adjustable) |

| 7 | Boundary Dimension | mm | Length; depth; height 350:350:360 |

| 8 | Ultrasonic Frequency | Hz | 40k |

| 9 | Machine Weight | kg | 40 |

| 10 | Motion Trail | | Circular motion and near-circular motion |

Note: can increase the negative pressure devices for users, Minimum

screen to 5 microns.

Our Advantage

Our company is a ISO9001:2000 certification enterprise, we

cooperate with large domestic companies and some scientific

research units. The follow picture is our long term cooperator.

Our Service

1. We have thorough data to ensure the quality;

2. We provide detailed instruction an product information;

3. We provide 12 months quality warranty;

4. We have professional engineer team ensure to provide the most

professional equipment;

5. Professional engineers team can choose the right equipment for

you;

6. We can provide thorough after-sales service to ensure the proper

use of machine.

If you want to get more information of product, please contact us!